Views: 0 Author: Site Editor Publish Time: 2025-11-14 Origin: Site

When it comes to choosing a stainless steel sink, understanding the gauge of the metal is critical for determining durability, noise reduction, and performance. As commercial kitchen spaces, hospitals, restaurants, and hotels demand reliable fixtures that can withstand heavy use, choosing the right sink gauge becomes essential. This guide explores the key differences between 16-gauge and 18-gauge stainless steel sinks, offering B2B buyers insights into which material is best suited for commercial applications.

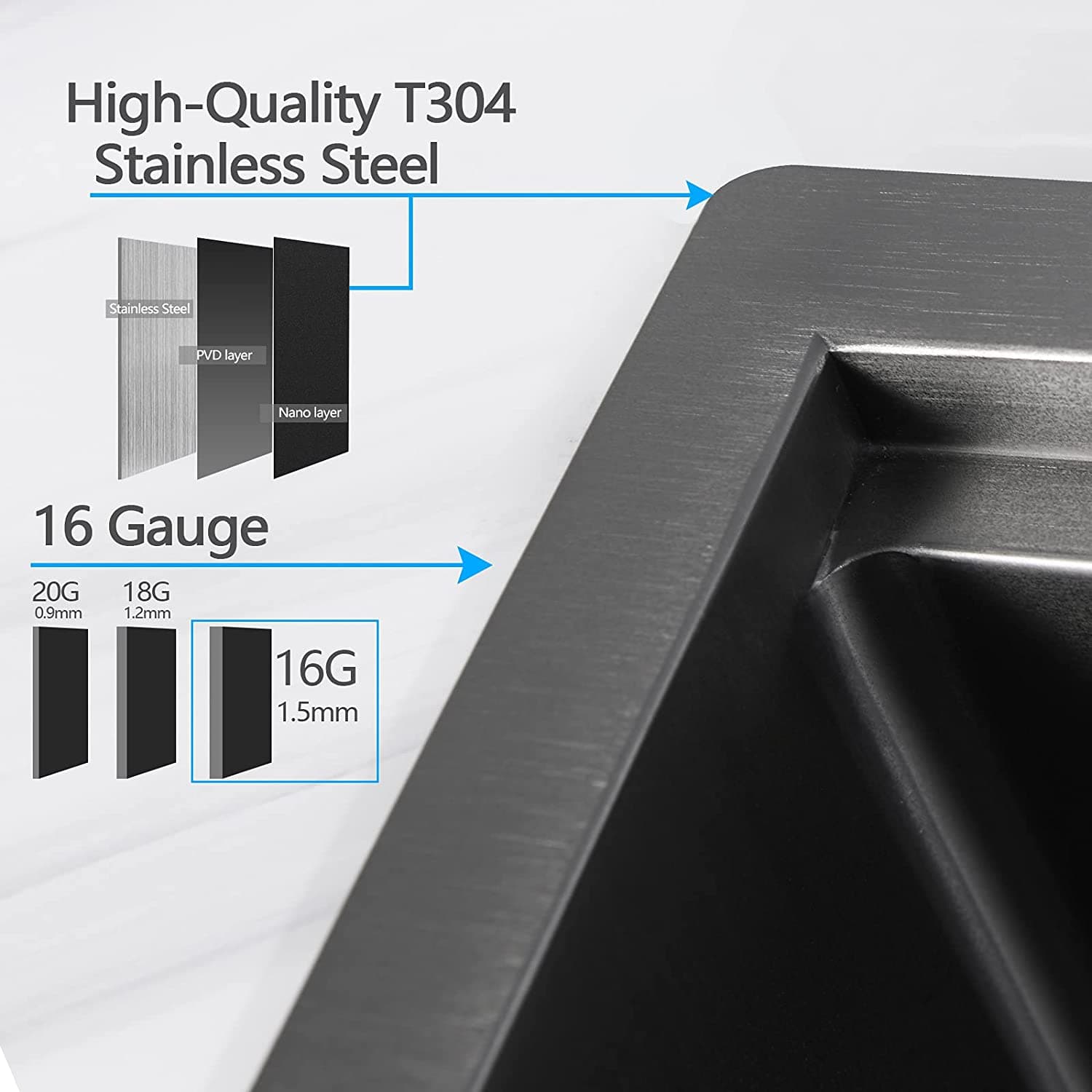

In the context of stainless steel sinks, the gauge refers to the thickness of the steel used. The lower the number, the thicker the steel and the more durable the sink. Gauge is an important factor that influences not only the sink's strength and resistance to dents, but also sound absorption, maintenance, and long-term performance.

For commercial kitchens or facilities with heavy daily usage, choosing the correct sink gauge can make a significant difference. 16-gauge sinks are thicker, more robust, and less prone to damage, while 18-gauge sinks are slightly thinner and lighter, making them a more budget-friendly option for less demanding environments. This article dives into the distinctions between the two, helping commercial buyers make informed decisions about their sink procurement.

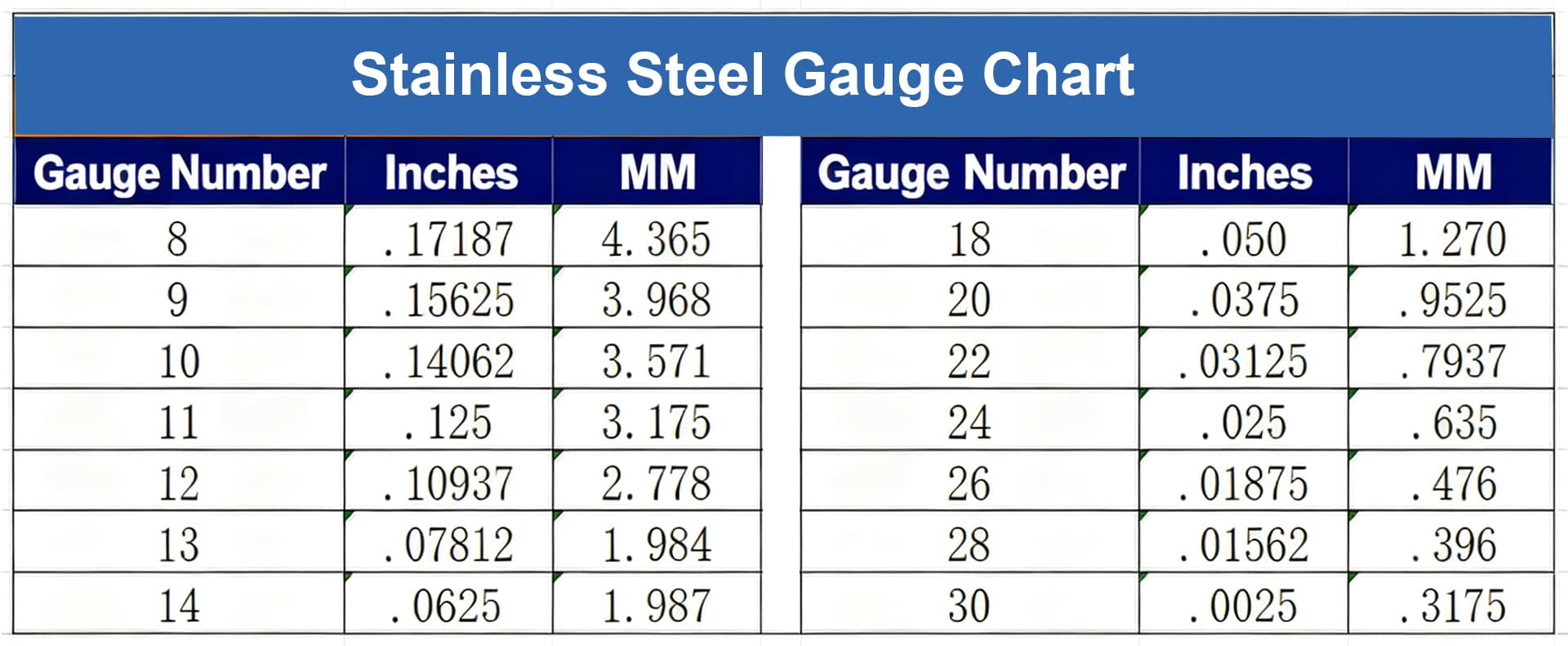

The gauge number system can be confusing, but it's simple once you understand it:

16 Gauge ≈ 0.0625 inches (1.59 mm)

18 Gauge ≈ 0.05 inches (1.27 mm)

The lower gauge number indicates a thicker material. This means a 16-gauge sink has more stainless steel, making it stronger, heavier, and more durable. 18-gauge sinks are thinner, more cost-effective, and often more suitable for light residential or commercial use. The choice depends on your sink needs—whether you're seeking maximum durability or a more affordable option that still offers solid quality.

Here’s a side-by-side comparison of gauge thickness:

A 16-gauge sink is built for heavy-duty environments, where constant use and the potential for dents and scratches are common. The thicker material resists deformation under high-impact conditions, such as from dropping heavy pots or utensils. This makes it ideal for commercial kitchens, restaurants, and hotels, where durability is key.

On the other hand, 18-gauge sinks are more prone to scratches and bowing under constant heavy pressure. While they’re still durable for most residential or light commercial applications, they can wear down faster in high-traffic areas.

One of the notable advantages of a 16-gauge sink is better sound dampening. The thicker metal absorbs more noise, creating a quieter washing experience. This is especially beneficial in busy kitchens where sinks are used often for washing dishes or for garbage disposal systems. In contrast, 18-gauge sinks tend to be noisier, causing more reverberation when water or dishes hit the surface.

Suitability for Heavy Use:

If your commercial kitchen sees high-volume use, a 16-gauge stainless steel sink is the better choice. It can handle the constant pressure and harsh cleaning environments. 18-gauge, while still functional for lighter commercial use, might struggle with wear over time, especially in environments where durability is critical.

When choosing between 16-gauge and 18-gauge stainless steel sinks for your commercial business, cost is a major consideration.

16-Gauge Sinks: Typically more expensive due to the thicker material and the added durability. However, these sinks offer long-term value as they require fewer replacements, offer better performance, and reduce maintenance costs in the long run. These sinks are ideal for high-end restaurants, hospitals, and hotel kitchens that require reliable fixtures for heavy daily use.

18-Gauge Sinks: A more budget-friendly option, perfect for light commercial environments or locations where the sink sees less heavy-duty usage. For instance, office kitchens or small cafés may benefit from 18-gauge sinks without compromising on quality, while saving money upfront.

The cost-benefit decision will depend on your business’s needs, usage, and budget constraints.

When sourcing stainless steel sinks, not all manufacturers offer the same level of quality. For a B2B buyer, it’s crucial to partner with a supplier that ensures:

True Gauge Construction: Some manufacturers may use inferior materials or cut corners with thinner construction. Ensure that your supplier offers certified true gauge construction, especially when purchasing 16-gauge or 18-gauge sinks.

Reinforcement: Reinforced corners and edges add structural integrity to the sink. Aquacubic, for example, uses reinforced 16-gauge stainless steel in commercial-grade sinks, ensuring that the product holds up to demanding environments.

Certification: Ensure that the supplier provides CUPC, NSF, or CE certifications for compliance with quality and safety standards. For example, Aquacubic’s sinks are certified by CUPC, ensuring they meet U.S. plumbing standards.

For B2B buyers, making an informed decision about which gauge to choose is crucial. Use this checklist to evaluate your purchase:

Gauge: Choose 16-gauge for maximum durability, noise reduction, and commercial use.

Material Grade: Opt for 304-grade stainless steel for corrosion resistance and strength.

Finish: Look for brushed or satin finishes for long-term aesthetic durability.

Soundproofing Features: Consider undercoating or sound pads to reduce noise.

Warranty: Verify the supplier offers a solid warranty (e.g., Aquacubic provides warranties for all commercial-grade sinks).

16-gauge sinks are thicker and more durable, with better noise control. They’re ideal for high-traffic commercial environments, while 18-gauge sinks are suitable for lighter use.

Yes, 16-gauge sinks are more resistant to dents, scratches, and warping, offering a longer lifespan under heavy use.

Look for certifications like CUPC or NSF and verify that the supplier uses true gauge material, not cheaper alternatives.

Thicker gauges like 16-gauge absorb more sound, making them ideal for high-volume kitchens. 18-gauge sinks tend to produce more noise when dishes or water hit the surface.

While 18-gauge sinks are more affordable, 16-gauge offers long-term cost savings through durability, making it the better option for high-traffic environments.