Product Category

What Are the Functions of a Steam Shower Room?

1. What Is a Steam Shower Room?

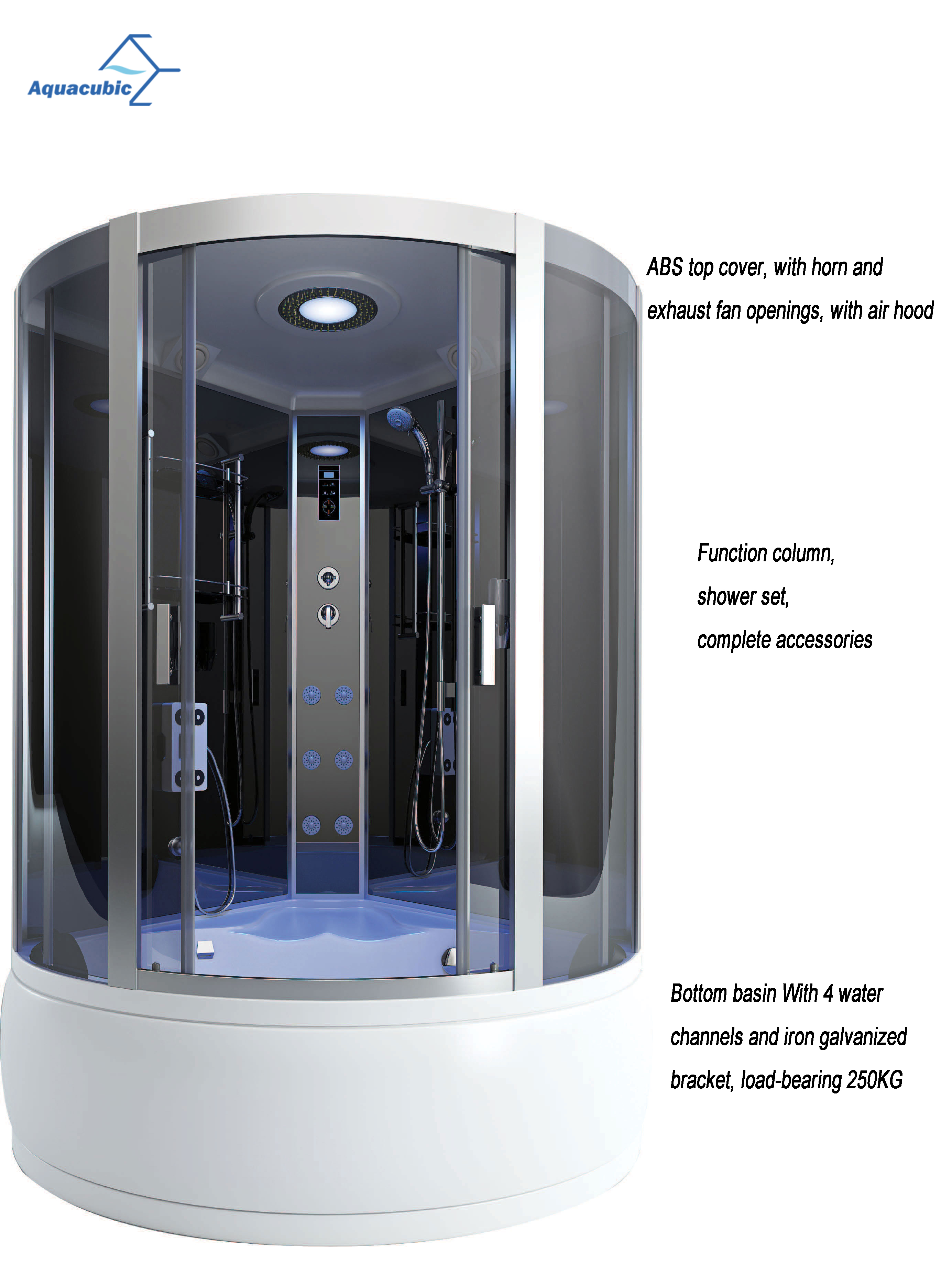

A steam shower room is an integrated bathroom fixture that combines the functions of a shower and a steam bath. It is mainly composed of a steam shower enclosure and a steam generator. The room is typically enclosed with tempered glass to ensure safety and durability, while also making the space look spacious and bright. Maintenance holes and removable panels are usually included to facilitate easy servicing of the internal steam generator.

The steam generator is the core component of a steam shower room. It generates steam by heating water, filling the room with warm vapor to simulate the effects of a sauna. This provides users with a relaxing steam bath experience. To enhance the user experience, modern steam shower rooms often come equipped with additional features such as massage nozzles, music playback systems, adjustable lighting, temperature controls, and seating, offering a comprehensive, comfortable bathing environment.

2. Types of Shower Rooms

Shower rooms can be classified into different categories based on their functions, styles, shapes, and materials:

- By Function:

- Integrated shower rooms (with more functions, often including steam features, also known as steam rooms).

- Simple shower rooms (basic shower enclosures without a "roof").

- By Style:

- Corner shower rooms, straight-line bath screens, arc-shaped shower rooms, bathtub screens, etc.

- By Chassis Shape:

- Square, circular, fan-shaped, diamond-shaped, etc.

- By Door Type:

- Sliding doors, folding doors, swing doors, etc.

- By Material:

- Tempered glass or acrylic panels, sometimes with additional textures like water ripple or fabric-like finishes.

Integrated shower rooms generally have more features and are higher in price but offer limited customization options. Steam-integrated shower rooms, also called steam rooms, are not suitable for individuals with heart conditions, high blood pressure, or for unsupervised children.

In contrast, simple shower rooms come in a variety of styles, are often more affordable, and typically lack a roof. They are made using materials such as ceramic, acrylic, or tempered glass, with configurations tailored to fit the user’s needs and bathroom layout.

3. Functions of a Steam Shower Room

A steam shower room is a modern shower fixture offering multiple functions, including:

1. Steam Bathing

- Its core function is generating high-temperature steam to create a sauna-like environment. This provides various health benefits, including:

- Muscle relaxation and pain relief.

- Enhanced blood circulation and metabolism.

- Detoxification and weight management.

- Improved skin health through deep cleansing.

2. Showering

- Offers standard shower functionality with various modes, such as overhead showers and handheld options, to meet daily hygiene needs.

3. Temperature and Humidity Control

- Allows users to customize the temperature and humidity settings for an optimal bathing experience.

4. Entertainment

- Equipped with features like Bluetooth speakers or music playback systems to enhance relaxation during use.

5. Lighting Effects

- Includes LED lights, often with adjustable colors or sync options with music, creating a soothing atmosphere.

6. Hydromassage

- Some models feature massage jets to relieve muscle tension and improve overall circulation.

7. Safety Features

- Includes explosion-proof glass, waterproof design, overheating protection, and automatic shut-off functions.

8. Energy Efficiency

- Designed with effective insulation to maintain heat and reduce energy consumption.

9. Convenience

- Features intuitive digital control panels for easy operation.

10. Aesthetic Appeal

- Serves as both a functional and decorative element, enhancing the bathroom's overall design.

Aquacubic Shower Room Material:

1 Tempering glass (tempered glass, monolithic, flawless, CE certified)

2 Aluminum material

3ABS (Tray/bass bottom; roof. 3-5 layer structure; ABS multi-layer board) or acrylic (Acrylic; PMMA; high-end product)

Production Process:

1 Forming (note: bubbles, cold bars, uneven thickness)

2 Apply grease (1 in three layers, bottom basin. 2 Use wooden strips and boards; 348 hours for drying; 4 2.5-3mm boards; 5Reinforcement with special reinforcement for edges, corners, and falling water; 6 24 hours for reaction time)

3 trimming edges (Nordic simplicity)

4 Assembly (warranty for 1-2 years; roof light, backlight, fan, Radio-12V can support)

5 Packaging

6 Glass processing packaging (corners, placed vertically as a whole)

7 Aluminum processing

8 Finished product assembly

9 Water test, blowing air (hold water for 24 hours)

10 Cleaning, packaging, and boxing