Views: 0 Author: Site Editor Publish Time: 2025-11-25 Origin: Site

Faucets are simple to operate but technically sophisticated behind the scenes. For procurement managers, showroom buyers, specifiers, and contractors, a deep understanding of faucet components, finishes, certifications, installation checks, and common failure modes is essential for selecting products that perform reliably across years of heavy use. This guide breaks down every major faucet part and accessory, explains its function and typical failure modes, provides practical usage and maintenance tips, recommends reputable brands, and offers a pre-shipment and on-receipt inspection checklist for B2B buyers.

A faucet is both a utility device and a long-life product. A poorly chosen faucet can lead to high warranty claims, dissatisfied clients, and costly replacements; a well-chosen faucet reduces service calls, conserves water, and protects brand reputation. Buyers should evaluate materials, valve type, finish durability, certifications, and after-sales support in combination—not just price.

Key standards and certifications to look for include lead-free and public-health marks as well as efficiency labels. For example, EPA’s WaterSense program identifies water-conserving fixtures and details how aerators and flow controls reduce consumption.

Below are the main parts of a faucet, with plain-English descriptions tailored for procurement and technical teams.

Function & use: Sits at the spout tip. Mixes air into the stream to reduce splash while maintaining perceived pressure; limits GPM (gallons per minute).

Why buyers care: Aerators save water and can be swapped for different flow rates (e.g., 1.5 GPM vs 2.2 GPM). They are the easiest part to service if flow drops due to mineral scale. EPA WaterSense guidance emphasizes the role of aerators and flow restrictors in saving water.

What to check on receipt: Ensure aerator threads match spout (male/female), note gpm rating, keep spare inserts for service.

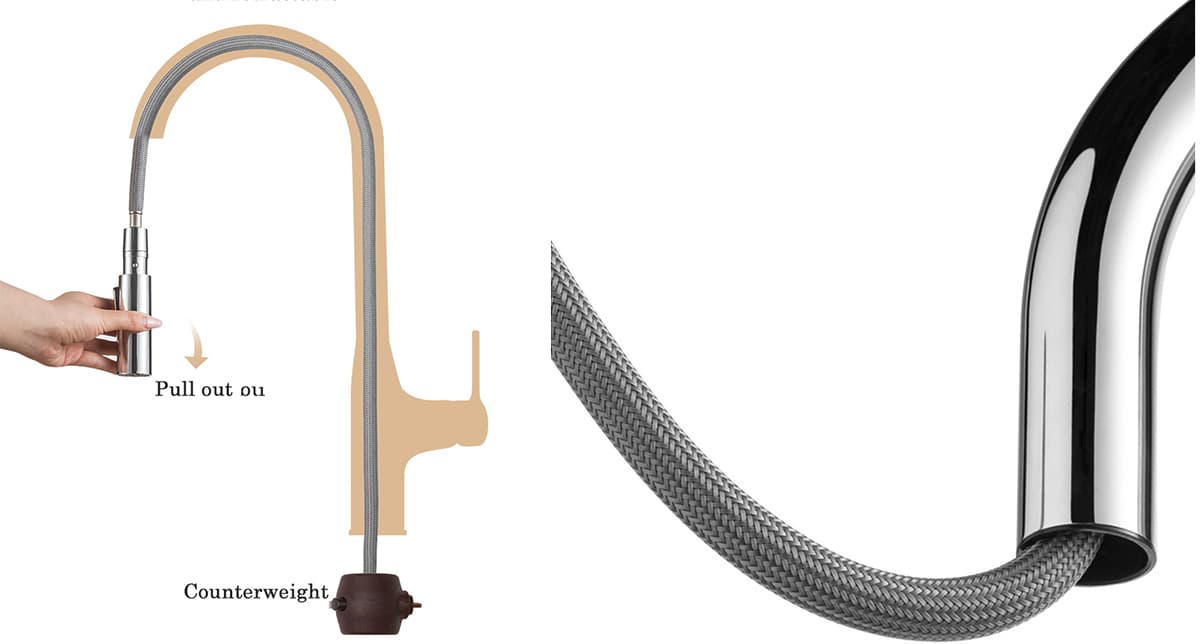

Function & use: Delivers water into the sink. Variations: straight (bathrooms), high-arc/gooseneck (kitchens), pull-down/pull-out (spray head on hose).

Procurement tip: For commercial kitchens choose high-arc or pull-down models with robust hose fittings and metal-reinforced hoses. For ADA or bar applications select lower-reach spouts.

What to check: Smooth rotation (if swivel); leak-free connection at spout base; no wobble in pull-out hose retract mechanism.

Function & use: Manipulates water flow and temperature. Single-lever controls are common for quick one-hand use; dual-handle systems offer finer temp control. Sensor and touchless controls are increasingly popular for hygiene.

Buyer note: Touchless models require power (battery/AC) and may need spare batteries and a maintenance plan. Many top brands now offer sensor models with industry-leading reliability—see brand list below.

What to check: Smooth actuation, return to off position, sensor range settings (for touchless), and wiring/connector robustness.

Function & use: Regulates flow and mix of hot/cold water. Common types: ceramic disc (long-lasting), cartridge (common and serviceable), compression (older style).

Why it matters: Valve quality determines leak resistance and lifetime. Ceramic disc valves are the most durable and are standard in high-end and commercial faucets.

What to check: Type is specified on datasheet; stocked spares for high-use applications; service documentation from manufacturer.

Function & use: Structural core that houses valves, supports spout/handles, and forms the visible exterior. Configurations: single-hole, center-set, widespread, wall-mount.

Procurement note: The body material (lead-free brass, stainless steel, zinc alloy) affects longevity and compliance. For drinking water applications, low-lead brass or stainless steel is recommended. Certifications often require limited lead content.

Function & use: Secures the faucet to deck or wall; escutcheon covers multiple holes and gives a finished look.

Inspection tip: Ensure included mounting bolts, gaskets, and mounting plates are present and correctly sized. Check escutcheon finish uniformity.

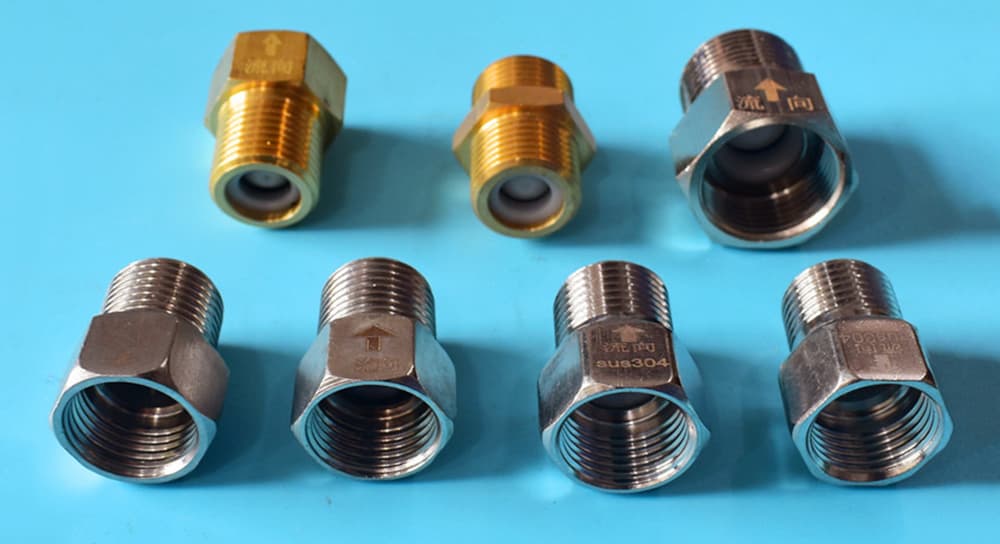

Function & use: Flexible braided supply lines carry hot and cold water from shutoffs to faucet inlets. Common fittings: 1/2" NPT, 3/8" compression.

Buyer guidance: For commercial installs choose stainless steel braided lines with rated working pressure; check connection sizes to match site shutoffs.

What to check: No kinks, proper crimping, pressure rating on the hose, and presence of anti-vacuum check valves where required.

Function & use: Prevents contaminated water from flowing back into potable supply. Required in many jurisdictions for certain installations (e.g., pot fillers).

Compliance note: Always confirm local plumbing code; ensure product documentation shows backflow prevention if spec requires it.

Function & use: Provide watertight seals between moving parts and threaded joints.

Maintenance tip: O-rings are common replacement items. Keep spares in service kits and specify material (EPDM, nitrile) for chemical resistance.

Function & use: In pull-out spouts, a flexible hose and weighted gravity ball ensure retraction.

Inspection: Make sure the ball is secured, hose glide is smooth, and the spray head docks properly without leaks.

Function & use: The spray head delivers alternate spray patterns (stream, spray, pause). Diverter valves switch water between spout and sprayer.

Troubleshooting: Diverter issues often cause partial flow or inability to switch modes; usually solved by cleaning or replacing the diverter cartridge.

Function & use: Installed behind aerators or inlets to deliver controlled, non-splashing laminar flow in healthcare settings.

Where used: Laboratories, healthcare, and foodservice often require laminar flow devices for splash containment.

Hides extra holes; choose plate finish to match faucet. For renovation projects, keep multiple hole covers in mind.

Integrated soap dispensers reduce clutter; side sprayers are less common now due to pull-down convenience but still useful in high-capacity kitchens.

Specialty faucets for filtered drinking water require NSF certification for contact materials; ensure compatibility and proper isolation valves.

For thicker countertops or undermount sinks, extension shanks or specialized mounting adapters ensure proper clamp pressure and sealing.

Avoid overtightening threaded connections. Overcompression damages gaskets and threads—hand-tighten and finish with a quarter turn with a wrench.

Match flow rates to application. Use 1.5 GPM or WaterSense-rated aerators where conservation is important; use higher flows only where needed. EPA WaterSense resources help identify compliant products.

Prevent scale by installing inlet filters where water is hard. Aerator clogging is the most common complaint; periodic removal and vinegar soak restore flow. See Home Depot’s maintenance guidance.

Use manufacturer-approved replacement parts. Cartridge and valve replacements from the OEM avoid cross-compatibility issues.

Power plan for touchless units. Verify battery type or AC adapter access, and plan maintenance intervals for power sources.

Below are common faults with diagnostic tips and pragmatic fixes that field technicians can use.

Likely causes: Worn valve/cartridge, damaged seat, or debris.

Fix: Isolate shutoffs, remove handle and cartridge, inspect O-rings and ceramic discs, replace cartridge if worn. Home Depot troubleshooting lists common steps. The Home Depot

Likely causes: Clogged aerator, blocked flexible supply, partial shutoff.

Fix: Remove and clean the aerator (vinegar soak), inspect supply line for kinks, verify shutoff fully open. See consumer advice for low pressure solutions. Better Homes & Gardens

Likely causes: Loose gravity ball, hose friction, debris in guide.

Fix: Check gravity ball weight and attachment, lubricate hose glide (non-petroleum product), replace hose if frayed.

Likely causes: Dirty sensor window, low battery, wrong sensor range setting, plumbing air in sensor valve.

Fix: Clean sensor window, replace batteries, reset sensor range per manual, purge air from lines.

Likely causes: Abrasive cleaners or hard water.

Fix: Use manufacturer-approved cleaners. For PVD or specialized finishes, follow brand care instructions; PVD finishes are more scratch-resistant but still benefit from gentle cleaning.

Lead-free brass (recommended): Excellent machinability and longevity; often required for drinking water fittings. Verify low-lead certification.

Stainless steel: Highly corrosion resistant; preferred in modern commercial kitchens and hygienic environments.

Zinc alloy / zamak: Lower cost, acceptable in low-use residential fittings but not recommended for long-term or potable water heavy-use applications.

Chrome: Durable, economical, easy to match.

Brushed nickel / stainless look: Hides scratches.

PVD (Physical Vapor Deposition): Superior scratch resistance and color stability; generally more durable than electroplated finishes.

Powder coat / specialty: Check adhesion and salt-spray resistance for commercial use.

Inspection point: For plated finishes, request salt-spray and hardness test reports if the buyer requires long warranty life.

When specifying or sourcing, reputable manufacturer brands matter for support, spares, and certification records. Below are well-known brands and representative resources:

Moen — reliable cartridges and motion sensing (good service network). (Brand overview)

Kohler — premium design and broad product range. (Brand overview)

Delta / Brizo — innovation in spray tech and touchless. (Brand overview)

Grohe / Hansgrohe — European engineering and finishes; strong in integrated systems. (Brand info)

Pfister — strong certification transparency, ADA and lead-free listings.

Kraus / KES / Kitchen specialty brands — value options with growing certification lines.

Aquacubic— durable construction and eco-friendly materials.

Use this checklist when a pallet of faucets arrives at your warehouse:

Package & labeling

Confirm invoice and packing list match: model codes, finish, quantity.

Inspect cartons for transit damage (crushed edges, water stains).

Verify serial numbers or batch codes where issued.

Visual & dimensional checks

Remove 1–2 samples per carton for visual check of finish uniformity and label correctness.

Measure center-to-center, spout reach, height, and hole spacing against cut-sheet.

Functional checks (on sample units)

Mount sample on test board; check rotation, handle movement, diverter action.

Turn on water supply and test hot/cold mixing; observe for leaks around base and cartridge.

Test aerator flow rate (use simple bucket/time test or flow meter).

For pull-out models, test hose length, docking, and retract action.

Material & certification

Verify material certificates (lead content, stainless steel grade) and certification labels (cUPC, NSF, WaterSense) match purchase order requirements.

Finish & coating checks

Check plating for discoloration, flaking, or rub-off; inspect matte and PVD finishes under daylight.

For PVD items, request hardness or adhesion test certificates if required.

Accessories & spares

Confirm presence of escutcheons, mounting hardware, supply hoses, spanner tools, and spare aerator inserts.

Document all nonconformances

Photograph issues, segregate defective batches, and notify supplier with clear evidence for RMA.

When writing RFPs or tender specs, be explicit:

Material: “Low-lead forged brass (≤0.25% lead) for all wetted surfaces” or “304 stainless steel body”.

Valve type: “35mm ceramic disc cartridge, replaceable in situ.”

Flow rate: “1.5 GPM aerator unless otherwise indicated; WaterSense certification preferred.”

Finish: “PVD finish with 72-hour neutral salt-spray resistance, or equal.”

Warranty: “Minimum 5-year warranty on finishes and valves, 1-year full replacement on defects.”

Spare & service: “Supplier to provide 1% spare cartridges and aerator inserts with first shipment.”

Testing: “Supplier must provide cUPC / NSF certificates and material certificates with shipment.”

Q1:What valve type should I specify for long service life in commercial applications?

A:Specify ceramic disc or high-quality cartridge valves (35 mm or larger). They are less prone to leakage and endure heavy daily cycles.

Q2:Do I need PVD finishes for hospitality projects?

A:PVD provides superior scratch resistance and color stability over electroplating; it’s recommended for high-touch, high-visibility installations where aesthetics and longevity matter.

Q3:How do I verify a faucet is truly lead-free for potable water?

A:Request third-party test reports for lead content (e.g., NSF/ANSI 61, NSF/ANSI/CAN 372 or supplier’s lead-free statement) and check that the supplier’s product pages display certification marks.

Q4:What are the most common warranty claims and how to reduce them?

A:Drips (cartridge failures), finish wear, and hose leaks. Reduce claims by specifying robust valves, thicker materials (lead-free brass or stainless), and PVD or high-quality finishes.

Q5:What must be included in the incoming QC process to avoid costly returns?

A:A combined visual, dimensional, functional and certification check as outlined above. Document evidence and segregate nonconforming goods for supplier action.